contact us

- Phone : 09136847590

- Email: info@saeedmaleki.com

- Address: Dolat Abad Industrial Zone, Isfahan, Doktor Hasabi St. (No. 20) - Phase 2 - Plate 54

Latest posts

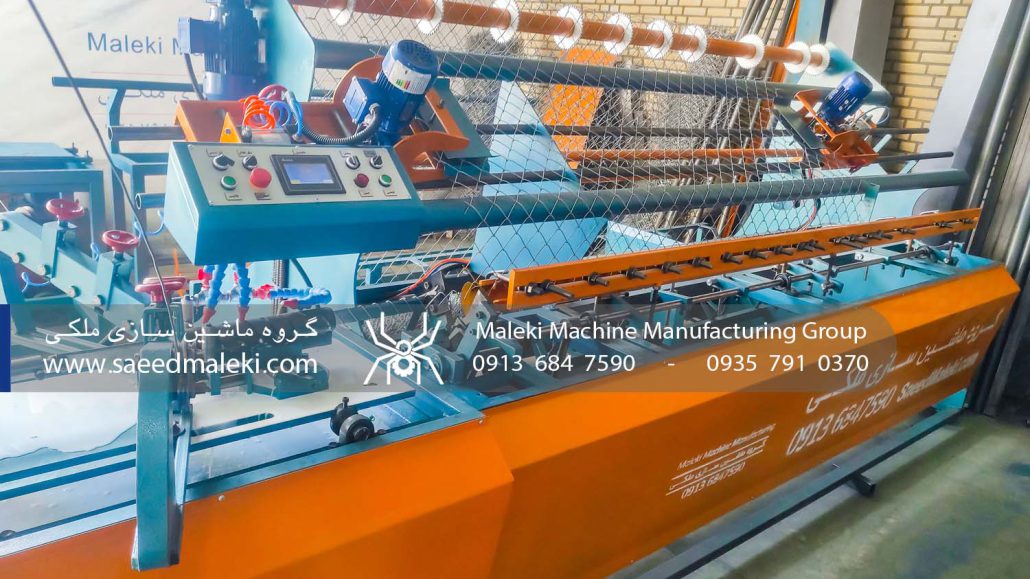

- Fence weaving machine

- Fence weaving machine template

- The price of a fence weaving machine

- ?What is a fence