Fence weaving machine

?What is a fence weaving machine

The fence weaving machine is an industrial machine that weaves a string of metal wires together in the form of a weft (rhomboid shape) and turns it into a connected and meshed network, which is called a fence or fence net. they say. The fence weaving machine takes two strands of wire from the input part of the device and twists the wire with a blade and mold, and after cutting it to the desired size, it delivers a woven net by repeating this step.

Types of fence weaving machines

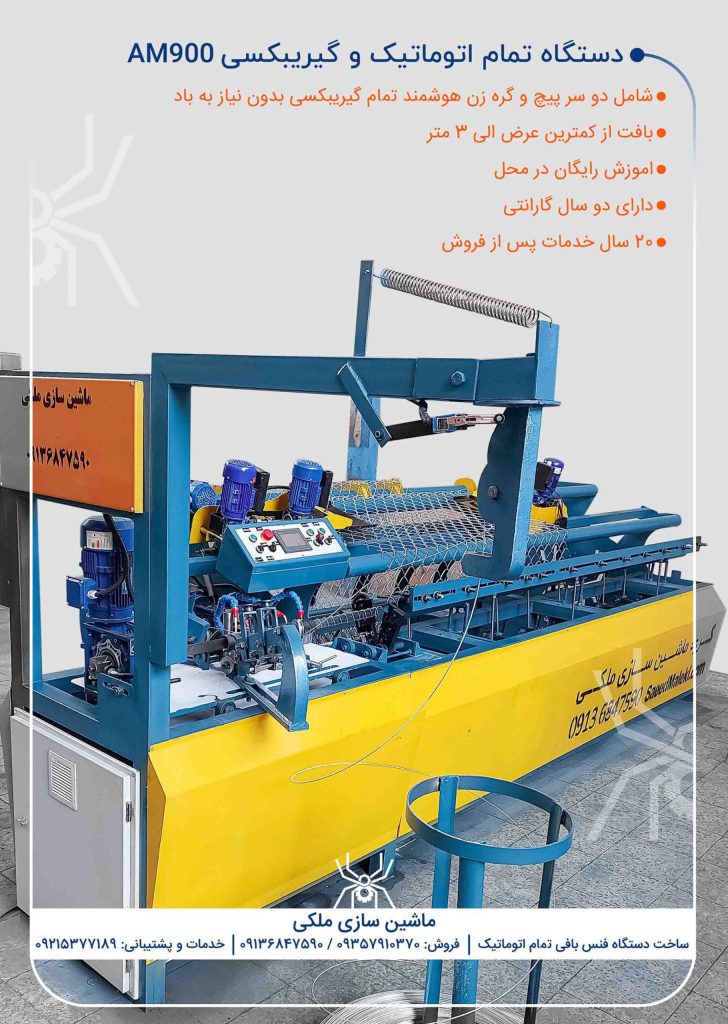

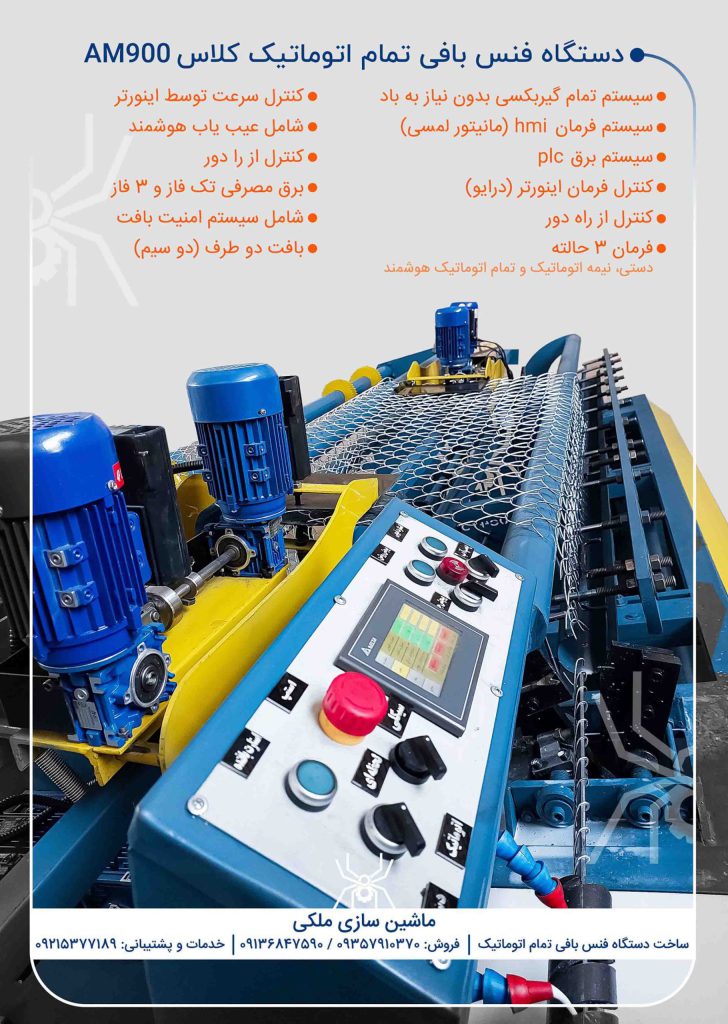

- AM900 fully automatic fence weaving machine – fully mechanical, 100% automatic – fully automatic and does not need to be upgraded.

- A900 model fully automatic fence weaving machine – mechanical and pneumatic – 100% automatic – it is fully automatic and does not need to be upgraded.

Semi-automatic fence weaving machine model - AM600 – two mechanical and pneumatic screws – 90% automatic – can be upgraded to automatic.

Semi-automatic fence weaving machine model - A600 – automatic structure – 80% automatic – can be upgraded to automatic.

- A200 semi-automatic fence weaving machine – automatic weaving – 50% automatic – can be upgraded to automatic.

- Manual fence weaving machine model A – automatic weaving – 30% automatic – is not produced due to low production capacity.

Share the contents of this page with your friends:

Application of fence weaving machine

?What are the uses of the fence weaving machine

The fence weaving machine produces fences and fence nets, which are used to enclose agricultural lands and orchards, and fencing for livestock.

The fence weaving machine is a family of wire industry devices that is mostly used in agriculture, horticulture and animal husbandry to protect and prevent the entry of wild animals and strangers.

Automatic fence weaving machine

?What is a fully automatic fence weaving machine

The automatic fence weaving machine is a machine that performs all the steps of fence production fully automatically. The automatic fence weaving machine is the most complete and advanced example of the machine among the set of fence production machines, which can produce the largest amount of fence netting or fence in less time.

Today, modern technology can be used in the best possible way in industrial work to save time and increase production. The use of modern and advanced and automatic equipment in any industry can increase the efficiency of manufacturing companies and factories and increase its efficiency.

Specifications of the automatic fence weaving machine

AM900 fully automatic and fully automatic machine

Dimensions and weight of the automatic fence weaving machine

*Length: 2 meters

*Width: 4 meters and 30 centimeters

*Height of the device: 1 meter and 50 centimeters

* Mast height: 2 meters and 50 centimeters

*Weight: 1300 kilos

Semi-automatic fence weaving machine

?What is the automatic fence weaving machine

The semi-automatic fence weaving machine is a device that weaves the fence neither fully manually nor fully automatically, it performs the work of producing the fence. In this way, part of the fence weaving steps are done by the operator of the control device and part of the fence weaving is done automatically.

Types of semi-automatic fence weaving machines

The semi-automatic fence weaving machine can be classified into different models. The production of fence with a semi-automatic machine has several advantages compared to the manual model of the machine: 1- Semi-automatic fence weaving machine that performs about 30% of the work steps automatically. 2- Semi-automatic fence weaving machine that performs about 50% of the work steps automatically. 3- Semi-automatic fence weaving machine that performs about 90% of the work steps automatically. 4- The semi-automatic fence-weaving machine, in addition to performing 90% of the work steps automatically, the appearance of the machine has been beautifully designed and is a suitable example for export.

? what models is the semi-automatic fence weaving machine made

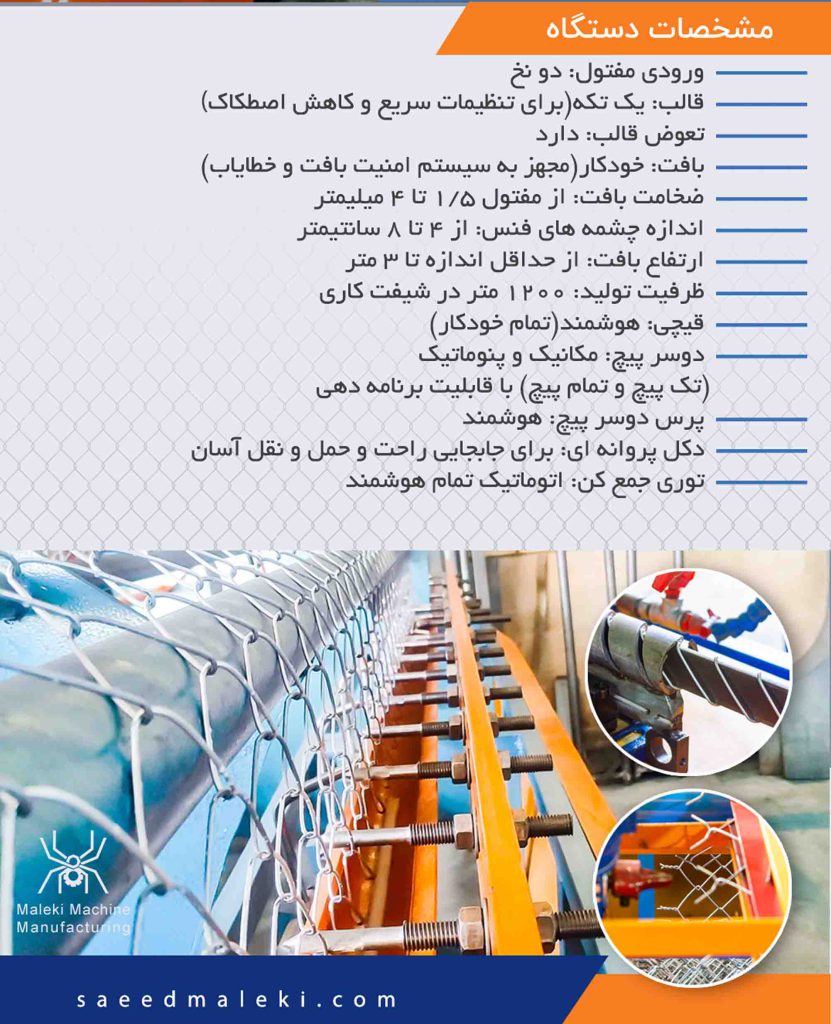

Technical specifications of the semi-automatic fence weaving machine

Wired input: Donakh

Mold: One piece (for quick adjustments and reduced friction) Format

change: Yes Automatic

texture: equipped with texture security system and error detector)

Fabric thickness: from 1.5 to 4 mm

wire Size of fence springs: from 4 to 8 mm

Texture height: from the minimum size to 3 meters (can be increased as customized)

Production capacity: up to 150 meters per hour

Scissors: Smart (fully automatic) Double

screw: mechanical and pneumatic – single screw and full screw Double

screw press: all smart

Device mast: collapsible (for easy handling and easy transportation

Net collector: fully automatic and intelligent

Features of semi-automatic fence weaving machine

?What are the features of the semi-automatic fence weaving machine

Twisting the two ends of the sides of the braided fence in the ultra-advanced manual fence weaving machine is superficial and if it is more complicated, it is done manually by the operator, but in the semi-automatic lace weaving machine, a part has been added that performs the work of making the two ends of the fence and The device operator has no role in this section. By performing the process of making the fence double-headed automatically like a fully automatic fence-weaving machine, the woven arch has a more beautiful appearance than the manual type of two-headed screws, and the number of screws can be adjusted, both of which increase the strength of the roll fence. raises The second feature of the semi-automatic fence weaving machine is the rolling of the woven arch, in this part the operator of the semi-automatic netting machine does not do anything, and the netting is automatically rolled. In fact, the two parts of screwing the fence and automatically rolling the net are done at the same time as the fence is woven, which actually lightens the operator’s work and increases the weaving speed and increases the production of the fence.

Technical specifications of the semi-automatic fence weaving machine

Mechanical characteristics of semi-automatic fence weaving machine

*Wire input: two wires

* Intelligent troubleshooting system

* Mold: one piece (for quick adjustments and reducing friction)

* Mold change: from spring 4 to 8 cm

* Mold fixture: for quick mold replacement

* Mold cooling system

* Texture: automatic (equipped with texture security system and error detector)

* Tissue thickness: from 1.5 to 4 mm wire

* The size of the springs of the fence: from 4 to 8.5 cm

* New texture channel (open channel) view the texture while working

* Texture height: from the minimum size to 3 meters

*Production capacity: 800 meters per shift

*Production capacity of the machine: designed for three work shifts

* It has a complete intelligent drainer

* Scissors: intelligent crankshaft

*Tori collect: smart

* The ability to change the length and width of the texture: intelligently while working

* Quick and easy settings

* Propeller mast: for easy handling and easy transportation

* Ability to upgrade to fully automatic machine with full option

Electronic characteristics of semi-automatic fence weaving machine

* Power system: PLC

* Control panel: HMI (touch screen)

* Speed control: inverter (drive)

* Security sensor: wire and texture input

* Electricity consumption: single-phase domestic and three-phase industrial

* Control system: Remote

* Amount of electricity consumed: 9 amps

* System update: online

Dimensions and weight of the semi-automatic fence weaving machine

*Length: 2 meters and 50 centimeters

*Width: 4 meters and 30 centimeters

*Height of the device: 1 meter and 50 centimeters

* Mast height: 2 meters and 50 centimeters

*Weight: 750 kg

Manual fence weaving machine

?What is a manual fence weaving machine

The manual fence weaving machine is one of the first machines that was designed and built to produce fences. At the beginning of manual fence weaving, there were many problems that severely limited the production capacity of fences and netting. In order to increase the production of fences and nets, the working hours or the number of shifts or the number of devices had to be increased, which also increased the cost of the fence.

“Note: The manual fence weaving machine has been left out of the manufacturing and production program in Maliki machinery due to the low volume of production compared to the higher class fence weaving machines”.

The history of making a manual fence weaving machine

How was the fence weaving machine invented

One of the reasons for starting a work or making a device is usually the feeling of need and the existence of difficulties to meet the need, and this feeling of need and doing many trials and errors has led to the creation of a work and the creation of a device. This limitation has caused some people to work and solve that problem. By studying a little about the history of the formation and invention of any industry or device, we realize that these people spent a lot of time researching and investigating and then started making a test sample or a small sample in the form of a replica of that device. For example, people have dreamed of flying for years until finally in 1903, this dream was realized by the Wright brothers. One of the industries that is not exempt from this rule is the design and manufacture of fence weaving machines. Since the invention of each device starts with the construction of a very basic and simple sample and is later developed by other people; The fence manufacturing industry was first started in a professional way to create protection and security with the invention of barbed wire, which was done by Michael Kelly.

Making a manual fence weaving machine

The advanced manual fence weaving machine is an updated manual fence weaving machine. In the advanced design and construction of the manual fence weaving machine, the basic defects of the manual fence weaving machine, which both caused difficulty in production and reduced the production capacity, were tried to be fixed and its performance optimized. The advanced manual fence weaving machine is currently one of the best-selling machines. which can be planned to set up a low-cost fence weaving workshop. Setting up a small workshop for weaving fences and producing fences and netting can be an attractive proposition that can meet the major needs of people and individuals and also earn good income for the producer. One of the very important and basic criteria that should be taken into account when starting any work, including the production of fences and netting, so as not to face problems in the future, is the financial part and its initial investment. The manual fence weaving machine is a unique offer for those who want to enter the labor market and does not require a lot of investment. One of the problems that can discourage a person from starting or at least face a challenge when starting a production job is the capital that must be anticipated for the purchase of equipment and raw materials. The advanced manual fence weaving machine is more logical and defensible because it is suitable for this work than its higher level machines.

Advantages of advanced manual fence weaving machine

- Advanced manual fence weaving machine because most of the work is done by the operator; It is very suitable for starting work, and it will be easier to finance it than a semi-automatic fence weaving machine.

- After buying a high-tech fence weaving machine, you don’t need a lot of different raw materials, and you can start the production of fence weaving manually by just buying some wire.

- The manufacturing time of the advanced manual fence weaving machine from the time of ordering to the delivery of the machine is very short, and the production of the fence can be started quickly.

- How to operate the ultra-advanced manual fence weaving machine is very easy and can be fully mastered with a few hours of training in a day or less.

- The production of fences can be done with an advanced manual net weaving machine with a minimum number of people (one person), which has a significant effect on reducing the current costs of the workshop.

- The manual fence weaving machine can be upgraded to a semi-automatic machine or a fully automatic machine at any time, and you can experience an increase in fence production by upgrading.

The best advantage of the advanced manual fence weaving machine

The best advantage of the ultra-advanced manual fence weaving machine is that in order to increase production, it can be upgraded to a semi-automatic and fully automatic fence weaving machine at any time by making changes and adding desired parts.

Technical specifications of the advanced manual fence weaving machine

*Wire input: single thread

* The ability to change the format: Yes

* Security sensor: wire and texture input

* Texture speed control: Yes

* Texture height: 3 meters

* Electricity consumption: single-phase domestic and three-phase industrial

* Installation, training and commissioning: free

*Warranty: 2 years

*After sales service: 20 years

*Sending the device to all of Iran is free

* Upgradability: to a semi-automatic device and a fully automatic device

Dimensions and weight of advanced manual fence weaving machine

*Length: 2 meters and 50 centimeters

*Width: 4 meters and 30 centimeter

*Height of the device: 1 meter and 50 centimeters

* Mast height: 2 meters and 50 centimeters

*Weight: 750 kg

Advanced manual fence weaving machine after-sales service

*Shipping, loading and sending the device for free

* Free training and installation at the buyer’s place

* One year warranty

*10 years of after-sales service

The price of a fence weaving machine

Factors affecting the price of fence weaving machine

The price of the fence weaving machine depends on the facilities that are used in its construction. The most effective items in the price of a fence weaving machine are scissors, two screws, and an automatic net gatherer.

When it is said that the fence net production machine works automatically or automatically and it has a higher price than non-automatic or semi-automatic fence weaving machines, the thought comes to mind that the fence net machine must work without an operator, if That is not the case. Facilities that are not available in the advanced manual fence weaving machine and which the operator must do are built into the automatic fence weaving machine. Fence scissor is one of the tasks that was done by the user of the device in non-automatic devices, but in the automatic device, fence weaving is done mechanically by the scissor section. One of the items that increases the price of the device is adding the scissor part of the device. After the scissors, there is a chocolate-can item that twists the wires using this item, and before this, it was done by the operator. A chocolate can or double screw also adds an amount to the total price of the automatic fence weaving machine. The third part that differentiates the price of the automatic fence weaving machine and increases the amount is the unloader of the machine. The end part of the automatic fence weaving machine is the collecting net of the machine, and after the complete weaving of the wire, the intelligent unloader collects the fence in a roll and the work of emptying the fence is done.

The price of a fully automatic fence weaving machine

?How is the price of the automatic fence weaving machine calculated

Due to the fact that all stages of fence production are done automatically, the automatic fence weaving machine has the highest price among all fence weaving machines. Items affecting the price of the fully automatic fence weaving machine: Automatic scissors Automatic screwdriver Automatic net gatherer (roller).

Sale of fence weaving machine

The best-selling fence weaving machine

Buying a fence weaving machine can be a good start to start a business that has a good income. In recent years, with the strictures applied by municipalities and agricultural jihad for walling gardens, surrounding fences and fences have increased greatly. Especially in cities where horticulture and agriculture are the main occupations, the production and sale of fences and nets is very profitable. On the other hand, the price of fencing around the land or garden is much more reasonable than the cost of walling. With a rule of thumb, it can be concluded that cities with many gardens and agricultural land are the best options for buying a fence weaving machine, and it is easy to start producing fences with a fence weaving machine at a reasonable price.

The cheapest fence weaving machine

The cheapest fence weaving machine is a manual machine. The price of the manual fence weaving machine is lower due to the fewer features it has compared to the semi-automatic and automatic machine, and it also has a lower production.

The most expensive fence weaving machine

The most expensive fence weaving machine is a fully automatic machine. The price of the full option fence weaving machine is higher because it has all the facilities for automatic fence production.